The water-resistive performance of the building envelope is critical for structural integrity (reference nearly every recent catastrophic building collapse), indoor air quality (organic growth formation), humidity/moisture control, component deterioration and rot, etc. HTL has a complete suite of field tests to evaluate a building's water-resistive performance with lab-quality data and comprehensive report deliverables.

AAMA 501.2-15

Quality Assurance and Diagnostic Water Leakage Field Check of Installed Storefronts, Curtain Walls and Sloped Glazing Systems [sic]

AAMA 502-21

Voluntary Specification for Field Testing of Newly Installed Fenestration Products

AAMA 503-14

Voluntary Specification for Field Testing of Newly Installed Storefronts, Curtain Walls and Sloped GLazing Systems [sic]

AAMA 511

Voluntary Guideline for Forensic Water Penetration Testing of Fenestration Products

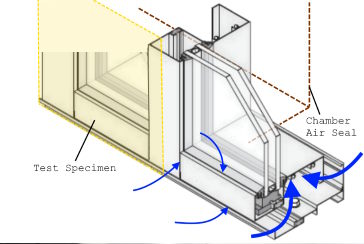

ASTM E1105

Standard Test Method for Field Determination of Water Penetration of Installed Exterior Windows, Skylights, Doors, and Curtain Walls, by Uniform or Cyclic Static Air Pressure Difference

ASTM E783

Standard Test Method for Field Measurement of Air Leakage Through Installed Exterior Windows and Doors

On-Site Mockup

Save cost and improve awareness of critical system detailing and transitions among on-site personnel. Rather than a remote location with, often times, little involvement from key on-site installers and documentatation of critical detailing/remediation lost in the subsequent reporting - consider an on-site or local "mini-PMU" with participation from all building envelope trades (e.g. block, framing, sheathing, vapor barrier install, rain screen, metal panels, windows, etc.).