Scope

The method includes two testing protocols:

- Protocol 1 (Test to Fracture) – Determines the maximum force required to cause detachment.

- Protocol 2 (Pass/Fail Testing) – Assesses whether the coating withstands a specified minimum load.

Originally developed for metal substrates, ASTM D4541 is now widely used to evaluate air and water-resistive barriers (AWBs) on sheathing materials, including gypsum board, plywood, OSB, and cement board. This application has become the predominant use of the standard, as the test provides quantifiable, repeatable data on adhesion strength, a critical factor for long-term building performance.

Unlike shear-based adhesion tests, D4541 measures tensile (or pull-off) strength, allowing for a more direct assessment of bond integrity.

^ Back to Top

D4541 in Air Barrier Testing: Significance and Broader Applicability

Although originally designed for metal substrates, D4541 is now the primary standard for air barrier adhesion testing on sheathing-based assemblies. Its widespread adoption is driven by its ability to quantify adhesion strength under field conditions, providing essential data for building envelope performance.

Critical for Air Barrier Performance

Adhesion strength is a fundamental characteristic of air barriers, ensuring that they remain bonded to the sheathing over time. Early adhesion failures during construction may indicate long-term deterioration, as a low initial bond strength increases the risk of progressive failure. If adhesion is compromised, air infiltration can migrate behind the barrier, drying and prying it away from the substrate over time. This process can lead to localized or widespread detachment, reducing the barrier’s effectiveness and contributing to moisture ingress and air leakage.

Even when adhesion appears sufficient at installation, long-term durability must be considered. Field testing with ASTM D4541 can identify weak adhesion early, allowing corrective actions before the barrier is enclosed within the wall assembly.

Limited Alternatives for Testing Sheathing Materials

While ASTM D7234 is a similar pull-off test method developed specifically for coatings on concrete, it is not commonly used for sheathing-based air barriers. In the absence of a widely adopted, sheathing-specific adhesion test, D4541 has become the default method for evaluating air barrier adhesion to gypsum, plywood, and OSB.

Some manufacturer-led industry trade groups have developed their own adhesion test standards for air barriers, but these methods often serve to minimize stringent oversight while protecting their members from unfavorable adhesion criteria. As a result, D4541 remains the most recognized and independent test method for evaluating adhesion in real-world construction applications.

^ Back to Top

Using D4541 on Sheathing-Substrate Air Barriers

Since sheathing materials differ significantly from metal substrates, certain adjustments must be made when applying ASTM D4541 to air barrier testing.

1. Substrate Rigidity and Fastening Considerations

- Unlike metal, gypsum board and plywood are semi-rigid and can deform or delaminate under tensile loading.

- Tests performed on thin or poorly fastened sheathing may reflect substrate failure rather than true coating adhesion failure.

- Test agencies must carefully consider the mode of failure and use professional discretion when interpreting results.

2. Selection of Adhesive for Dolly Attachment

- The adhesive used to attach the dolly (loading fixture) plays a critical role in test validity.

- Two-component epoxy adhesives are commonly used for strong, consistent bonds, though they usually require longer cure times.

- Hot glue is also frequently used, offering rapid adhesion without chemical interference. The heat generated by the glue must be considered against the substrate and air barrier material.

- Cyanoacrylate (super glue) or solvent-based adhesives may be utilized for self-adhered materials with facer layers, but their compatibility must be confirmed before use.

- Testing agencies should conduct preliminary test pulls to validate the adhesive selection for the specific air barrier material.

3. Influence of Moisture on Air Barrier Adhesion

- Sheathing moisture content can significantly affect adhesion results.

- If sheathing has been exposed to rain or high humidity before testing, results may underestimate adhesion strength.

- Some air barriers require priming before application; failing to follow manufacturer instructions may lead to artificially low adhesion values.

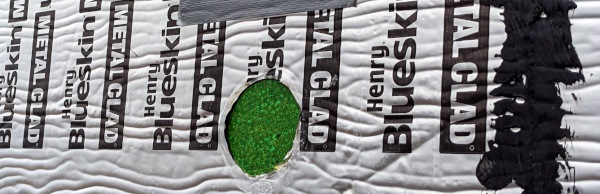

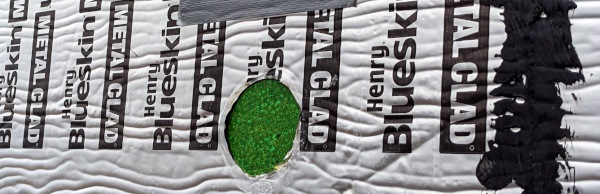

4. Scoring Around the Dolly

- Scoring around the dolly is a critical step in ASTM D4541 when applied to sheathing materials.

- Without scoring, the adhesion measured may include the contributing adhesion of the surrounding materials, leading to inflated results.

- Scoring isolates the adhesion of the area directly beneath the dolly, making the measurement more precise.

- However, care must be taken not to score too deeply into the substrate, as this can compromise the sheathing itself.

- If the sheathing fails at the scored area, the test result may not be predictive of actual air barrier adhesion failure—the intent of the test is to measure adhesion, not sheathing strength.

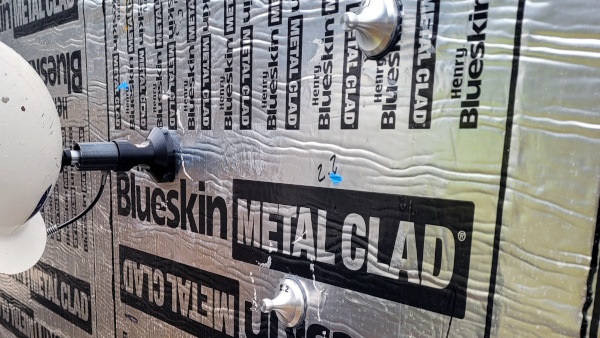

5. Dolly Selection and Function

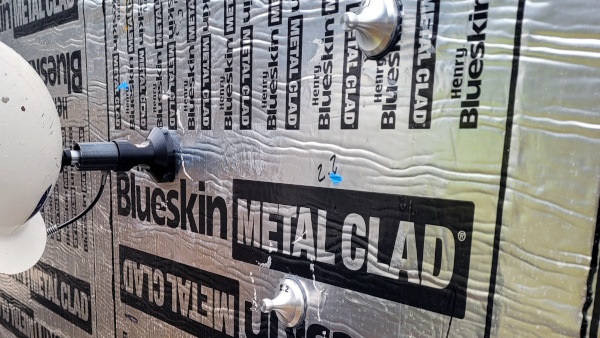

- The dolly (loading fixture) is a cylindrical object affixed to the air barrier to facilitate the test.

- Commercial dollies are typically metal cylinders, but in practice, a plywood cylinder with a bolt epoxied into it can also be used.

- The dolly must be strong enough to withstand the applied force without deforming, ensuring that failure occurs within the test specimen rather than the fixture.

- Dolly size should be carefully matched to the adhesion tester and expected adhesion strength to prevent premature or misleading failures. 50mm diameter is most common for air barrier adhesion, although 60mm may also be utilized. Regardless, the size must be specified and agreed upon by relevant parties.

6. Pull Rate and Test Conditions

- The rate of tensile load application affects results and should remain ≤1 MPa/s (≤150 psi/s).

- Slower rates are often preferred for sheathing-based tests, minimizing the risk of premature failure due to sudden stress application.

- Environmental conditions (temperature, humidity, glue cure time) should be documented to maintain consistency across tests.

^ Back to Top

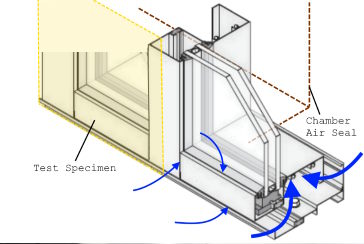

Test Procedure Overview

The test is conducted as follows:

- Surface Preparation

- Clean the test area to remove contaminants.

- If scoring is performed, ensure a controlled, precise cut around the dolly.

- Dolly Attachment

- Affix a metal or plywood dolly to the air barrier using a selected adhesive (epoxy, hot glue, or cyanoacrylate for certain materials).

- Use temporary tape or other means to temporarily affix the dolly while the adhesive cures.

- Allow the adhesive to cure per manufacturer recommendations.

- Load Application

- A portable adhesion tester applies a controlled, gradually increasing perpendicular tensile force to the dolly.

- Failure Analysis

- If the dolly detaches, the failure surface is examined to determine:

- Adhesive failure: Detachment between air barrier and sheathing.

- Cohesive failure: Tearing within the air barrier itself.

- Substrate failure: Delamination of gypsum or fiber pull-out from plywood/OSB.

- Sheathing failure due to scoring must be carefully reviewed—this may indicate a test-induced defect rather than an adhesion issue.

^ Back to Top

Conclusion

Although ASTM D4541 was originally developed for metal coatings, its primary use today is for testing the adhesion of air and water-resistive barriers to sheathing materials. The method provides quantifiable data on adhesion performance, supporting quality assurance, forensic analysis, and compliance verification in building envelope construction.

However, adjustments are necessary when testing sheathing-based materials. Test agencies must carefully interpret results, considering substrate rigidity, adhesive selection, scoring effects, and environmental conditions. Despite these nuances, ASTM D4541 remains the industry standard for field and laboratory adhesion testing of air barriers.

^ Back to Top