PROVEN BUILDING ENVELOPE SOLUTIONS:

Our Recent Projects

At Hightower Labs, we specialize in evaluating and improving the performance of building envelope systems. Our completed projects, some of which are showcased here, reflect our commitment to precision, problem-solving, and delivering actionable insights for building owners, developers, and design professionals.

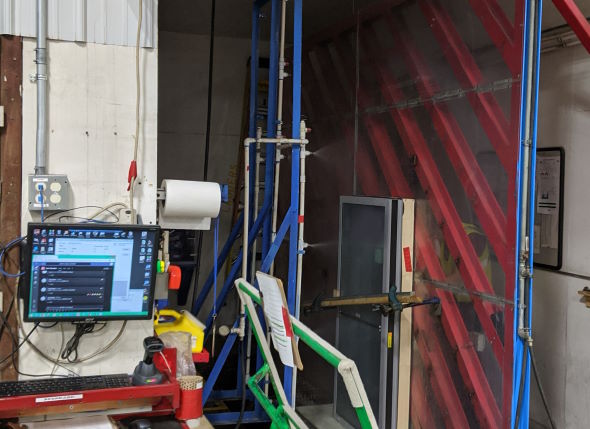

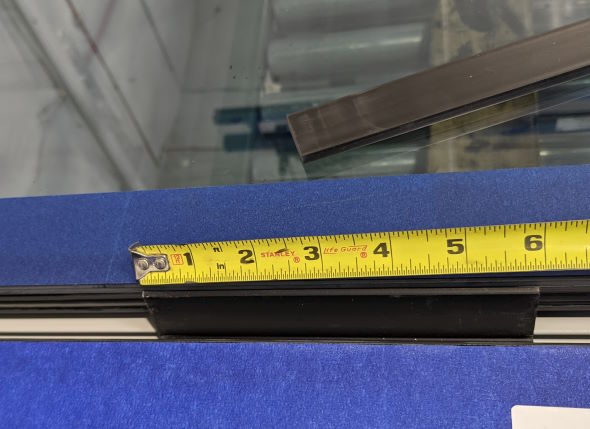

On-Site Evaluations & Performance Validation

We conduct comprehensive on-site evaluations of installed building envelope components, ensuring they meet design specifications, performance criteria, and long-term durability expectations. Our assessments provide clients with clear documentation and expert recommendations to validate completed envelope scope packages before project closeout.

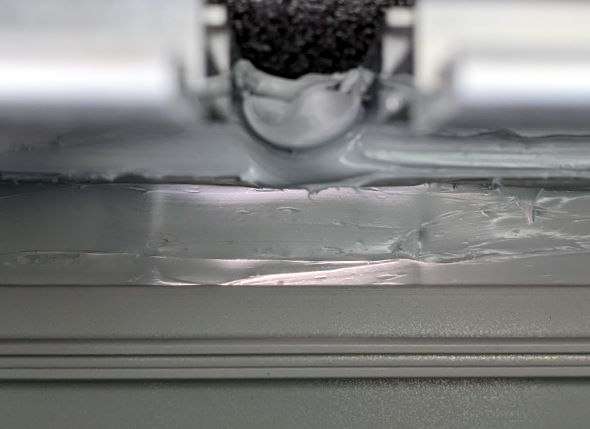

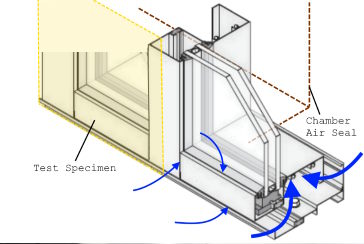

Leak Investigations & Water Intrusion Diagnostics

Water infiltration can be costly and disruptive. Our team specializes in identifying and diagnosing water intrusion issues, whether due to construction defects, material failures, or unforeseen environmental factors. Through field testing, forensic analysis, and advanced diagnostic techniques, we deliver clear findings and effective remediation strategies.

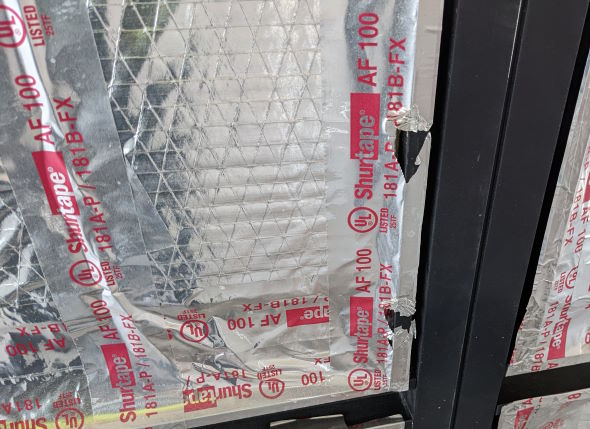

New Construction & Retrofit Assessments

For both new and existing buildings, our evaluations help stakeholders mitigate risks and optimize envelope performance. We analyze air, water, and thermal barriers to ensure proper integration and long-term resilience. Our work supports developers, architects, and contractors in refining construction details and ensuring compliance with energy codes and performance standards.

Supporting Litigation & Remediation Efforts

When envelope failures result in costly disputes, our forensic investigations provide clarity. We assist property owners, law firms, and insurance providers with detailed analysis and expert reporting to support claims, litigation, or remediation planning. Our unbiased, data-driven approach ensures stakeholders have the technical insights they need to resolve complex envelope-related issues.