ASTM E783 AND ALL-GLASS FACADES

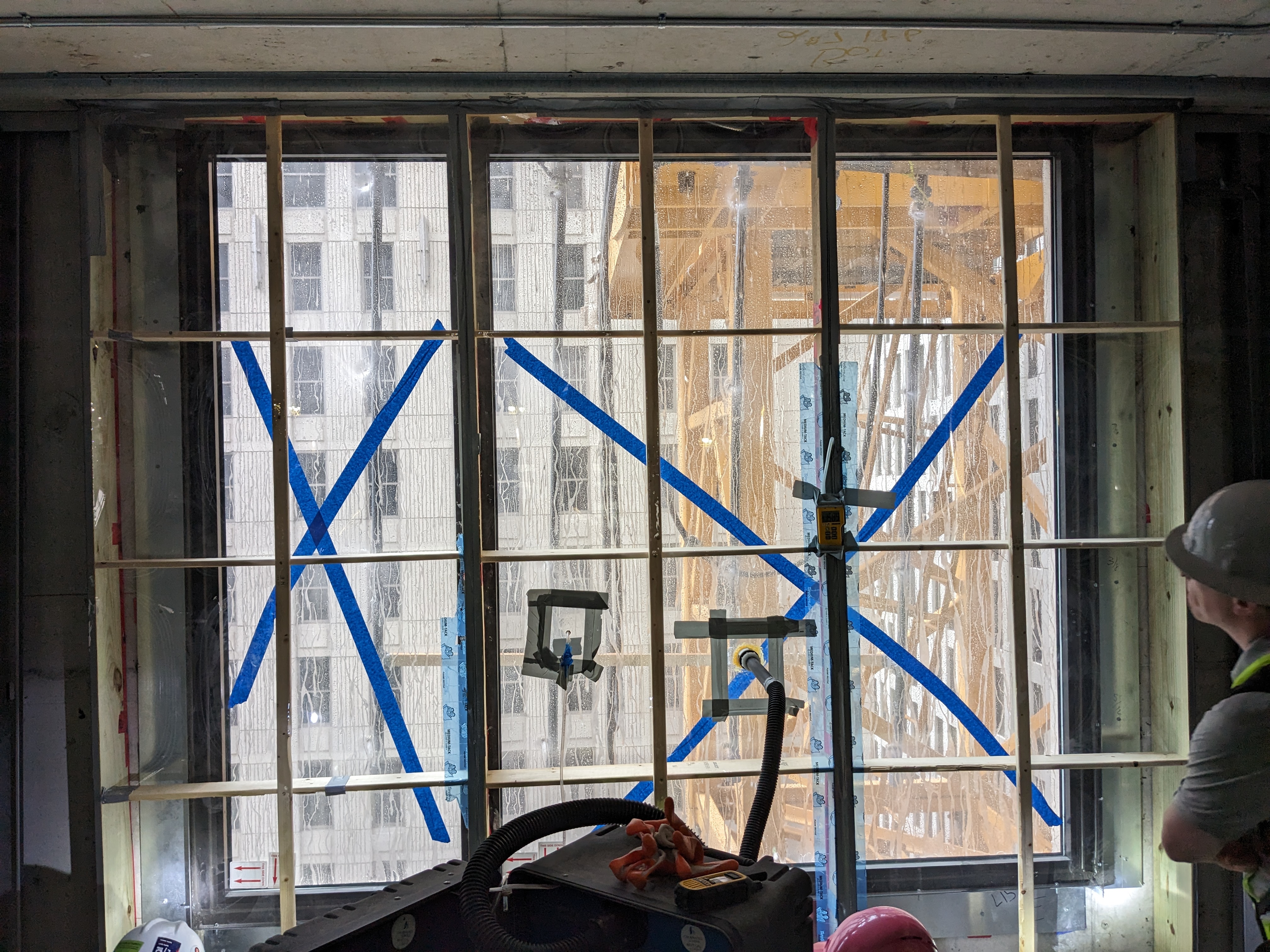

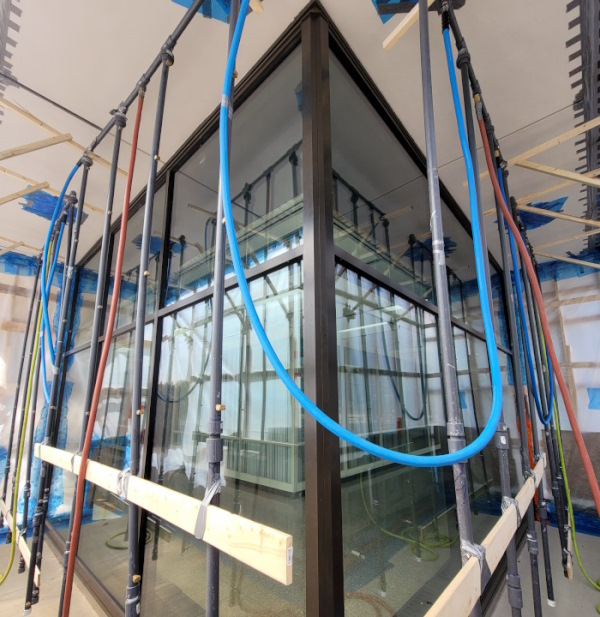

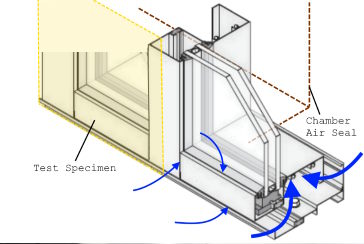

Industry-wide, invalid and improperly executed ASTM E783 test data are not providing a reliably accurate accounting of the building's air-tightness on window wall and curtain wall systems comprising the majority of envelopes built this century and, consequently, building stakeholders are blind to their property's performance.