NFRC 100 – U-Factor Measurement

Purpose: Defines the method for determining the thermal transmittance (U-factor) of fenestration products.

Key Concept: Lower U-factor values indicate better insulation (reducing the rate of exterior environment temperature affecting interior environment temperature), reducing the cost/energy to heat or cool the interior air.

Process: NFRC 100 requires simulation using NFRC-approved software, validated through physical testing. The procedure adheres to controlled conditions, including an interior temperature of 21°C (69.8°F) and an exterior temperature of -18°C (-0.4°F).

Reported Value: U-Factor (Btu/hr·ft²·°F or W/m²·K).

Relevance: Critical for energy code compliance and comparing product efficiency across multiple candidate products. Confirms that budgeted and proposed windows meet governing energy performance criteria, aligning with mechanical system design and preventing unexpected heat loss complaints from future occupants.

^ Back to Top

NFRC 200 – Solar Heat Gain & Visible Transmittance

Purpose: Establishes methods for determining Solar Heat Gain Coefficient (SHGC) and Visible Transmittance (VT).

Key Metrics:

- SHGC – Measures solar radiation admitted through a product; lower values reduce cooling loads.

- VT – Indicates visible light transmission; higher values improve daylighting.

Reported Value: SHGC (unitless), VT (unitless)

Process: SHGC and VT are determined using NFRC 201 and NFRC 202, utilizing spectrophotometric analysis, validated through testing.

Relevance: When considering various glazing coating and aesthetic options, this rating balances energy efficiency & daylighting for comfortable, cost-effective buildings.

^ Back to Top

NFRC 300 – Optical Properties of Glazing

Purpose: Specifies methods for measuring how glazing materials transmit and reflect solar energy.

Key Metrics:

- Visible Transmittance (VT) – Fraction of visible light passing through glazing.

- Solar Reflectance & Absorptance – Measures how glazing interacts with solar radiation.

Process: Spectrophotometric analysis is used to quantify glazing performance, with physical testing for validation.

Relevance: Essential for selecting glazing materials that manage heat and light effectively, and for daylight control.

^ Back to Top

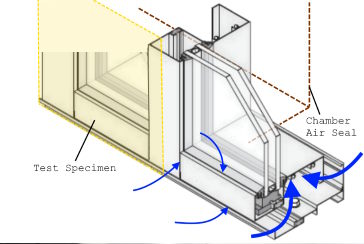

NFRC 400 – Air Leakage Testing

Purpose: Defines standardized methods for measuring air infiltration through fenestration products.

Key Concept: Lower air leakage rates indicate better airtightness, improving thermal efficiency & comfort.

Process: Testing follows ASTM E283 at a standardized pressure differential of 75 Pascals (1.57 psf). This procedure measures the volume of air that flows through a specimen while exposed to the specified (75 pa) interior/exterior pressure differential.

Reported Value: Air Leakage Rate (cfm/ft² or L/s·m²).

Relevance: A critical factor for energy conservation and comfort. Directly impacts heating/cooling costs, indoor air quality, and comfort. The majority of humidity transfer through envelope systems is the result of air leakage.

^ Back to Top

NFRC 500 – Condensation Resistance

Purpose: Specifies testing methods to determine a product’s resistance to interior surface condensation under controlled, defined environmental conditions.

Key Concept: Higher Condensation Resistance Factor (CRF) values indicate better performance in preventing condensation formation on interior surfaces under certain conditions.

Process: Evaluated under NFRC-defined conditions, including controlled humidity and temperature variations. Uses simulation and physical testing to output a rating (summarizing a product's risk of condensation formation) that might be used for comparison between fenestration products, or confirmation of compliance with governing criteria.

Reported Value: CRF (scale 1-100).

Relevance: Important for comfort, mold prevention, and building longevity. Important for quick reference to understand a system's generalized condensation risk under certain conditions. Actual performance depends on local humidity and ventilation conditions.

^ Back to Top

NFRC Simulation Manual – THERM & WINDOW

Objective: Guides professionals on thermal modeling software for fenestration products, providing criteria and methods for NFRC-compliant thermal modeling.

Key Tools:

- THERM – Models heat transfer in window assemblies, can provide condensation risk analysis of specific frame details.

- WINDOW – Calculates U-factor, SHGC, and VT.

Process: Guidance for these programs' tools and settings required for NFRC-compliant modeling methodology. Includes defining material properties, boundary conditions, and environmental loads for simulations.

Relevance: Used by manufacturers, architects, and consultants for product development, certification, verification & code compliance. A necessary component of NFRC verification.

^ Back to Top

Key Technical Definitions

Terms:

- U-Factor – Models heat transfer in window assemblies, can provide condensation risk analysis of specific frame details.

- Solar Heat Gain Coefficient (SHGC) – Calculates U-factor, SHGC, and VT.

- Visible Transmittance (VT) – Calculates U-factor, SHGC, and VT.

- Shading Coefficient (SC) – Calculates U-factor, SHGC, and VT.

- Air Leakage (AL) – Calculates U-factor, SHGC, and VT.

- Condensation Resistance Factor (CRF) – Calculates U-factor, SHGC, and VT.

^ Back to Top

Why NFRC Standards Matter

NFRC ratings create an objective framework for evaluating fenestration performance, ensuring consistency in product comparisons and regulatory compliance. NFRC testing creates a level playing field for comparing window, door, and skylight performance. These standardized procedures ensure:

- Apples-to-apples comparisons for product selection.

- Code compliance for energy efficiency regulations.

- Reliable performance data for architects, developers, and owners.

- Verification that proposed, submitted, and installed products have the capabiliy to meet contractual deliverables.

^ Back to Top

Final Thoughts

NFRC ratings don’t guarantee real-world performance, but they provide a baseline for making informed product decisions. Understanding these standards helps architects, developers, owners, and contractors ensure that fenestration choices align with energy efficiency goals, performance expectations, and project requirements.

^ Back to Top