Overview

This university residence hall in Chicago underwent a full renovation, including replacement of its fenestration systems. To confirm that the new ribbon window assemblies met project performance requirements for air and water resistance, the design team required third-party field window testing of the installed full opening, not just an isolated module.

“This wasn't about chasing a pass. It was about demonstrating that the delivered system could meet its obligations in the field.”

Hightower Labs was contracted to perform ASTM E783 air infiltration testing and ASTM E1105 water penetration testing across the entire multi-module assembly—engaging head, sill, jambs, receptor transitions, perimeter sealants, and field splices. This approach aligned the test environment with how the system was actually installed and used, yielding meaningful, project-relevant data—not assumptions.

^ Back to Top

System-Level Testing, Not a Sample

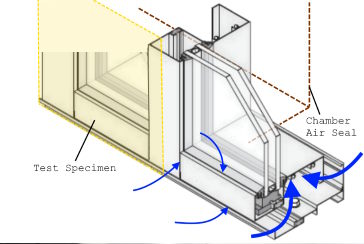

While many field tests focus on isolated units (single modules), this test evaluated the full system—head to sill, jamb to jamb—under sustained, repeatable pressure and water loading. The testing process involved:

- A full-size custom-built interior test chamber, sealed directly to the perimeter structure framing and primary air/water barrier

- A correctly executed polyethylene tare sheet process for ASTM E783, isolating true air leakage from extraneous chamber flow

- A complete 15-minute ASTM E1105 spray rack test, executed with calibrated equipment and verified pressure delivery

These methods ensured validity and repeatability—qualities rarely achieved in field testing environments.

^ Back to Top

Overcoming the Water Pressure Problem

On active construction sites, low water pressure frequently limits the ability to deliver ASTM E1105’s required 5.0 gal/ft²/hr. Many test providers address this by reducing spray rack size and testing smaller segments of the opening.

HTL took a different approach:

We deployed dual water reservoirs and independent pump assemblies, enabling full-surface water testing at the required rate without compromise. Spray rack delivery was pre-tested, pressure-verified, and monitored in real time. This method ensured the whole window system was tested in one piece, as installed—not in fragments.

^ Back to Top

Test Results

ASTM E783 – Air Infiltration

- Pressure Differential: 6.27 psf (300 Pa)

- Result: 0.02 SCFM/ft² (< 0.15 cfm/ft² - Pass)

ASTM E1105 – Water Penetration

- Pressure Differential: 5.29 psf

- Result: No leakage observed (Pass)

^ Back to Top

Why Full-Opening Testing Matters

Testing a single window module may pass on paper but fail to reflect how the system performs when integrated. Field testing the complete installed assembly confirms whether product, installation, and detailing align with project intent.

This project’s successful result did more than meet spec. It provided:

- Measurable proof of system performance

- Early-stage detection and resolution of potential weak points

- A documented record of QA/QC execution for the owner, architect, and construction team

HTL’s testing gave the entire project team something better than a passed checklist: confidence.

^ Back to Top

Deliverables That Stand Up to Scrutiny

At Hightower Labs, we believe a field test is only as valuable as the documentation that follows it. Within 48 hours of test execution, the project team received a clear, professionally prepared report that included:

- Full-page, high-resolution photography

- Clearly marked results and test parameters

- Concise technical summaries and test observations

- Commentary designed for both technical and non-technical stakeholders

Whether you're a project manager looking for confirmation, an architect reviewing integration, or an owner seeking assurance, our reports are designed to serve all audiences—without sacrificing rigor. They don’t just tell you it passed. They show you how and why.

^ Back to Top

Hightower Labs specializes in real-world building envelope performance testing, including ASTM E1105, ASTM E783, and custom field protocols. If you’re designing or delivering a system that must perform under pressure, we can help you prove it.

High level envelope performance demands real solutions. Contact Hightower Labs for expert field testing, window leak investigations, & building envelope consulting.

^ Back to Top